Automated Architecture (AUAR) is a UK-based technology company using data-driven learning and generative design to build a distributed micro-factory network for sustainable timber housing. The co-founder and chief technology officer, Gilles Retsin, is also an associate professor at the Bartlett School of Architecture, UCL.

Roland Snooks and Gwyllim Jahn (guest editors): How is AI used in your practice or products?

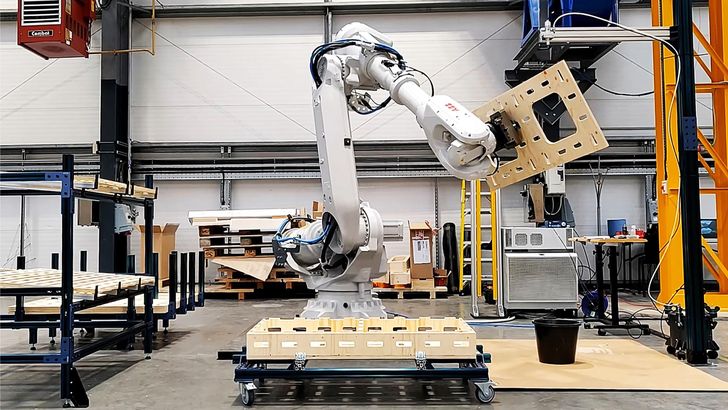

Gilles Retsin: AUAR’s tech stack comprises a building system based on timber blocks; a robotic cell that assembles the blocks from standard timber materials; and software that generates and evaluates fully functional, costed house designs. The software is an ecosystem of cloud-based apps and services that can be called either in the browser or in standard AEC packages such as Revit and Rhino. AI is most important for the configurator, which “blockifies” pre-existing 3D models and simple plan drawings into functional assemblies of timber blocks, windows and doors.

AUAR licenses its designs for low-capital-expenditure robotic micro-factories and tech stack to a network of existing home builders.

Image: AUAR

Another way we use AI is to learn from manufacturing designs and partners. When we supply the configurator with data from various partners and built designs, its output helps us understand real-world issues like construction time, recurring problems and cost. We can then use these insights to further close the gap between design and manufacture by effectively simulating the manufacture of a repeating, adaptable product.

Guest editors: What are some of the reasons for implementing AI?

GR: We primarily value the “autopilot” possibilities of AI: automating the transition from simple design intent to manufacturable designs, and reliable costing and timing predictions. This would allow architects who design with our systems to more quickly iterate and test, which has implications for cost and other performance criteria. Learning from the real-world projects of manufacturers that use our tech allows us to improve the product over time.

We see the combination of an open and simple building system with generative software and AI as a great alternative to the repetitive modular housing solutions that are currently on the market. This approach supports architecture-as-cultural-project in industrialized construction. On an economic level, it also solves the core problem of modular solutions that are a struggle to adapt to different sites, client desires and local constraints.

AUAR aims to enable the delivery of low-energy homes at the price of normal houses, and at scale.

Image: AUAR

Guest editors: How do you expect this to change in the future?

GR: We see a larger scope for AI in the future as our network of manufacturing partners grows and we collect more meaningful data. Increased automation in both the configurator software and the robotic manufacturing processes makes our technology more accessible and increases the flexibility and adaptability of our designs.

Guest editors: How long have you been using AI?

GR: We have been working with AI processes for a few years at AUAR’s academic sister, AUAR Labs, which is based at UCL. Within the company, work on the first version of the configurator software started mid-2022.